Tip

I noticed something about the VPX that I wanted to share. Since it’s kind of a long story I will start by stating what I found and will share the details afterwards. What I found was that if you are assigning multiple circuits/breakers to be controlled by a single switch there is some kind of prioritization done in the VPX when turning on and off the circuits. I have a request into Vertical Power to see if they can give me a more detailed explanation of how it prioritizes the circuits so that I can better reposition one of the circuits I have connected to it. Hopefully I’ll get an answer and can share this information.

So now the long story. I have a TCW battery backup and have my PFD, GNX375, COM1, and some of the Garmin avionics like the GEA and GAD on there as well. It’s basically there to keep a few important items on should the engine or alternator/main battery fail in flight. I have this labelled as “Essential Bus” on my panel. The TCW has a charging circuit which also acts as a sensing circuit that turns off the battery when it detects a voltage or on if the voltage isn’t there. The TCW manual recommends that this pin be connected to your main bus so when you turn on your master switch the battery turns off and the system then charges the battery. This appears to be a good way to connect it up, but for me it complicated my startup flow. The way I imagined my startup sequence is “Essential Bus” on… which tests that the battery backup is functioning and also gives you access o your main avionics should you want to load in a flight plan, check ATIS, etc. Also you can get your engine page up on the PFD prior to your engine start. Next is Master (Batt) on, then start the engine, then Master (Alt) on and then the avionics switch on, lights on, etc. Here’s the issue. As soon as you turn on your Master switch the TCW says oh there’s voltage on my sensing pin so I’ll turn off the battery and that nicely shuts down my PFD, GNX, COM1 and all the other stuff that was already powered up on the Essential Bus. The solution then is to make sure you turn on the avionics switch (which all that stuff is connected to as well) prior to turning on the Master, but that’s only kind of a solution because then as soon as you turn on the Master all of your avionics power up and you don’t have your engine running yet. Which I suppose it’s so bad now a days, but generally it’s best to have a stable power source prior to powering everything on.

My solution to the problem then was to put the sensing circuit to be controlled by the avionics switch which is very easy to do with everything running through the VPX. That way the battery will only turn off when I want all the avionics to be powered by the main bus and not the battery backup (Essential Bus) and that worked out nicely except when I turned off the avionics switch (while the Essential Bus switch was still on). What happened was my PFD and some of the misc Garmin stuff rebooted. This had me thinking that I guess the sensing circuit in the TCW wasn’t quick enough to switch to battery to provide power to that equipment so that was what caused the reboot and figured maybe I will fix it with some large capacitors or just live with the problem. Then I tried an experiment. This was to power up everything and then just kill the Master batt switch which basically turns everything off (including the VPX) all at once and low and behold the PFD and other Garmin stuff didn’t reboot so that told me that the sensing circuit in the TCW is very quick to detect a power outage and can quickly transfer over to battery. That then left the question why doesn’t it work when using the VPX to do essentially the same thing. My hypothesis was maybe the VPX was somehow ordering or prioritizing the circuits when shutting them down or powering them up.

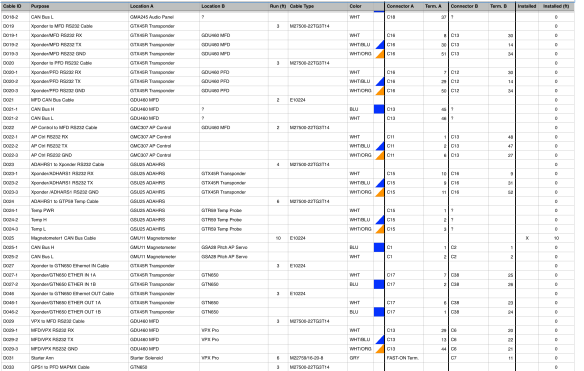

On to experiment #2. My TCW sensing circuit was on J12 pin 7, PFD on J8 pin 5 and misc Garmin equipment on J8 pin 1. I thought maybe it prioritizes by just starting from the lowest connector and pin so since I had J8 pin 2 open I temporarily moved the TCW sensing circuit from J12 Pin 7 to J8 pin 2 and like magic it worked perfectly. Not leaving well enough alone and also not wanting to use up a 10A circuit for a 5A load I then moved the TCW sensing circuit to J8 pin 7 which is a 5A circuit breaker. My thought was maybe if it’s all on the same connector the speed at which the VPX can turn off the circuits probably is negligible so it “should” still work. To my surprise though when I turned on the avionics switch the PFD rebooted which had never happened before. Turning off the avionics still worked fine. So now that leaves me with still a question of how the heck is this thing ordering the circuits. I’m thinking maybe it’s also taking into consideration the bank (The VPX Pro has 2 banks, A and B for redundancy) or maybe the breaker size, J8 pin 2 is a 10A circuit where J8 Pin 7 is a 5 A circuit so maybe it’s turning potentially high load circuits off first and on last. I’m hoping that their support can give me a good answer, but for now at least where I put the TCW sensing circuit seems to fix my issue.